Offerings

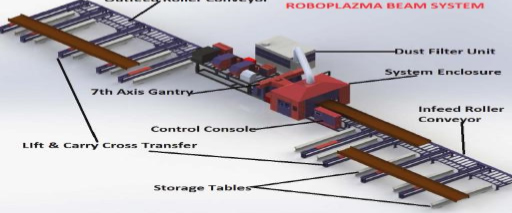

ROBOPLAZMA PLATE & BEAM SYSTEM

Features: Features:

- World’s first & only plate & beam plazma cutting system.

- Single System that offers 2D and 3D cutting capability.

- Shop floor tested Innovative design having more than 12 patents.

- Single RoboPlazma replaces Band Saw, Drilling, Coping, Notching

- Slotting, Pipe & Tube Cutting, Marking & CNC Plate cutting.

- Faster, smarter, and cost effective solution transforms plant throughout.

- Vibration free Moving Cantilever design delivers precision & smooth motion.

- Modular Hardware enables system expandability.

- Just 3 click software powering a machine that grows with user.

- Independent Measuring System give high accuracy.

- Underside processing without additional Robot.

- All side Square tube processing.

- Large Plate Cutting 2.5 x 30 Mtr. with weld edge preparation.

- Complex geometries like Mouse Hole being processed which are not achieved by competition.

- Pipe Cutting: Only system in the world where the pipe is cut without rotation.

- Pipe processing.

- Welding.

- Curved Beam/ Pipe processing.

- Dish End.

- 3D Assembly.

- Capable of marking Lay Out, weld Lines & part Numbers without Tool change.

- This is an intelligent fully robotically interfaced material handling system.

- Down draft fume extraction table for plate cutting and Unique design of system enclosure takes care of Ibeam cutting fumes efficiently.

Features: Features:

- A cantilevered moving Robot able to reach all sides and areas of the job

- This opens up opportunity for customers for underside processing Square Tubes, Pipes and complex geometries without investing for additional robot, chucks or pipe rotators.

- Single machine solution to fabricate I Beams, Channels, Angles, Tubes, Pipes and also Large Plate processing.

- Intelligent, cost-effective and flexible system gives you potential to meet multiple customer needs.

- Produce high quality Bolt Holes, approved by AISC and CISC.

- Bolt Hole sizes 2xThickness above 12 mm plate, No tool changing required.

- Produces all Standard and Non-Standard Copes.

- Produces Miter Cuts, Compound Miters and Double Compound Miters.

- Pipe Straight cut and Straight bevel.

- Produces Square Tube Slots for Knife connections.

- Beam Splitting and Beam Castellation.

- Produces lay-out on all sides.

- Processing Standard copes.

- Plasma Marking with all alpha numerical characters.

- Pre-Measures the raw material prior to processing.

- Probing of the raw material for mill tolerances and automatic adjustment.

- Scalable to Plate and beam system as your business grows.

- Flats size of 1000 mm width processed on Beam system for various 2D profile and shapes.

- Material Handling System

- Plasma Fume Filter

Features: Features:

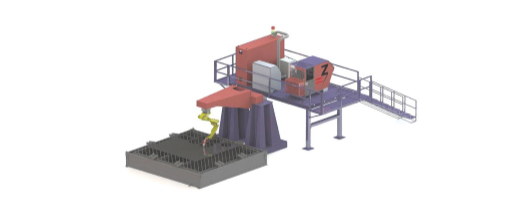

- Cost effective modular configuration of RoboPlazma system. A Fanuc, Japan make Robot mounted on fixed cantilever arm, interfaced with Plazma power source.

- This system is widely useful in Automobile industry for 3D component trimming and cutting, 2D and 3D jobs. No longer are trimming dies required for prototyping development.

- Reads direct CAD input and cut the formed sheet metal component. Effectively eliminating long lead time to manufacture trimming dies and enabling finished products to be launched faster.

- With a RoboPlazma work cell being used for production, any change of model or alteration, is just a question of programming; avoiding expensive retooling.

- From fixed robot, the system can be scaled up to moving cantilever RoboPlazma configuration. As your business grows, the systems grow with you.

Features: Features:

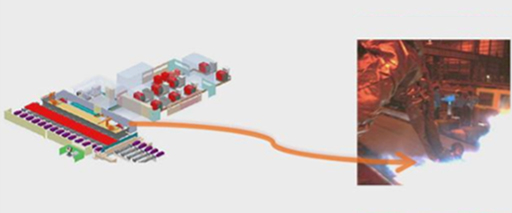

- Embedded with a plasma torch design that performs precise metal cutting at red-hot temperatures

- Mounted on an 8 axes robot

- Governed by proprietary self-calibrating software that governs the operation, diagnostics and troubleshooting eliminating the complexities of controlling a cutting system

- Engineered with a systems interface compatible with current steel production systems that facilitates the line integrations process and minimizes production disruption

- World’s first robotic unmanned self-intelligent red-hot steel cutting plasma system

- Interface compatibility with steel mill online systems reduces system integration time.

- The system has built-in intelligence to compensate for plates’ shape fluctuations, eliminating inaccuracies in cutting.

- The system software can command the robot to perform multiple subsequent uninterrupted cuts in material of different dimensions. Proprietary torch nozzle system allows precise cuts minimizing material yield loss.

- Automation eliminates the need for direct operator interaction, no safety risks associated with the processing of red hot metal.

Features: Features:

- It is manufactured with highest quality standard components such as FANUC Robots, Plazma Power Supplies, GUDEL Precision Rails and is controlled with a user friendly RoboSwift Software interface that accepts DSTV files. All axes are Servo driven for precision and accuracy.

- Large Plate Processing capability ( expandable up to 30 mtr Length)

- Auto Nesting and cutting.

- Automatic alignment of plate.

- Stitch Cutting capability.

- Single & Double Bevel.

- Consumable life monitoring system with cutting interlock

- Touch and Edge sensing thru Plazma torch.

- Auto Torch Height Control thru AVC tracking.

- Operator’s friendly “RoboSwift” Software.

- Expandability of “Roboswift” to plug in with scheduling software.

- Flexibility for new 3D job cutting.

- Weld Edge Preparation

- Beveling operation on different type of jobs can be carried out such as, Linear bevel on Plate, Circular contour beveling, Single / double bevel, ‘V’ Bevel with root with root, Flanges and web bevel of I Beam, Pipe, Beveling, 3D assemblies bevel.

- First system manufactured worldwide, capable of processing all structural shapes; also scalable, can be upgraded to cut large steel plates i.e. 2.5 x 30 Mtr. (using additional gantries).

- Combination of multiple processes on a plate with RoboPlazma™ eliminates repeated material handling and multiple machine setups, which leads to an increase of the entire plant throughput.

- Roboswift software automatically calculate the optimum base position of the robot for complete nesting capability.

- Estimated Work envelope with this configuration is 1.2 M x 30 M applicable for 2D/3D cutting, Single “V” with root beveling with larger work envelope for hole, slot, pipe, channel, Ibeam cutting.

Features: Features:

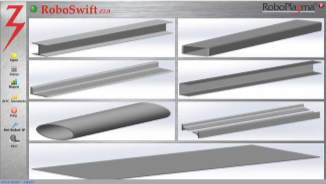

- RoboSwift™ is a software solution conceptualized, designed and developed by Plazma Technologies Pvt. Ltd. India to operate with RoboPlazma™. RoboSwift™ software along with RoboPlazma™ delivers a solution for robotic plasma metal cutting with minimal human intervention, controlling by itself the myriad components that work in the machine.

- RoboSwift ™ works inside the controller to minimize the errors of the robot.

- The operator needs zero robot programming knowledge.

- Operated on a touch screen through simple and intuitive graphical user interface. It requires no robotic or other programming knowledge to operate.

Features: Features:

- Plazma has developed a X-Y Robot (CNC-Plazma) system for 2D nested cutting application.

- System is designed like a Robot with separately located 4 axis Fanuc controller for high reliability and rigidity at highly competitive rates.

- System comes in width of 4M, 6M and 8M; to cover entire range of plate sizes from plate width of 3M to 6M. Length can be increased by adding Y Axis modules up to any length required.

- The system has been provided with auto torch height controller through arc voltage and touch sensing for piercing point.

- Multiple gas stations are also provided as per customer requirements.

Features: Features:

- Plazma’s unique US Patented “PIETA” mechanized torch mounted on simple linear trolley

- Used for linear & circular cutting up to 100 mm thickness.

- Provides faster cutting speed, better cut quality and longer consumable life hence highly economical solution for all steel plates.

- Four Wheel stable Trolley.

- High Speed 2000 mm/min with dual Speed setting.

- Long Slide Arm for horizontal torch movement.

- Fine adjustment for vertical slide.

- 2Mtr long MS rail.

- Cutting accuracy +/- 1mm.

- Bevel capability.

Features: Features:

- The US and worldwide patented Plazma torch technology combined with a rugged non-electronic power source presents the most reliable metal cutting tool.

- Extremely compact from 1mm to 75mm thickness provide capacity, reliability, ruggedness, economics and job repeatability in continuous production.

- Small size, light weight and easy to operate

- Water Cooled Design

- Stainless steel electrode housing

- Concentric & self aligned consumables

- Non metalic cover

- Safety remote switch

- CE-certified torch

|